Category

All New Gmu

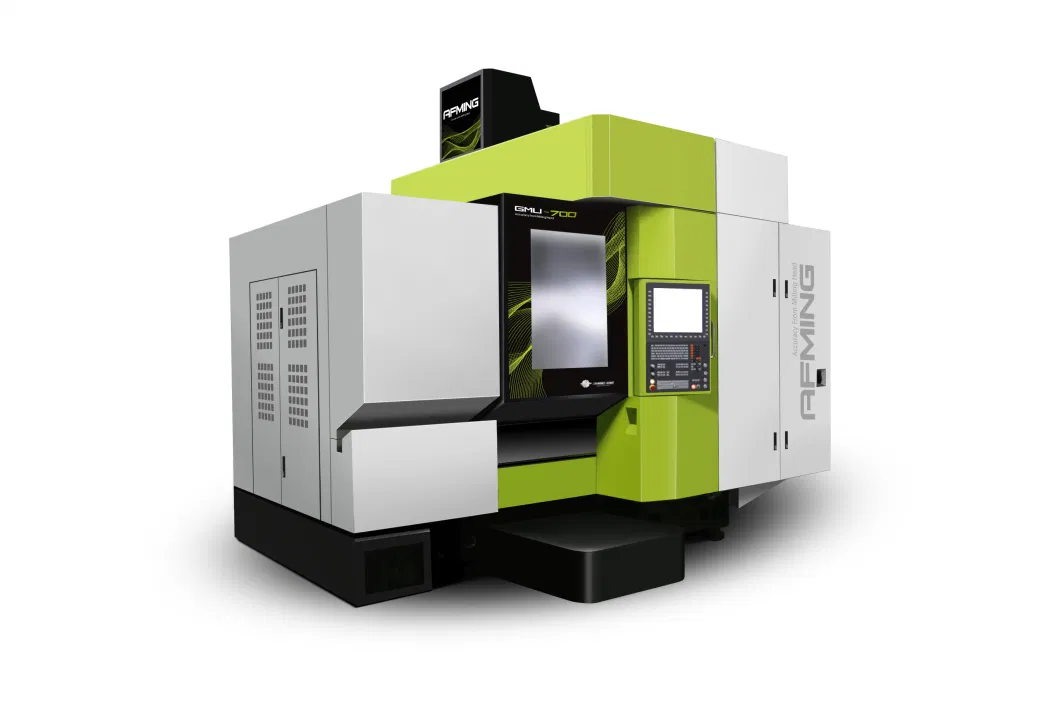

GMU-700 Five Axis Machining Center Introduction Achieve efficient and accurate five-axis simultaneous machining. Relying

Basic Info.

| Model NO. | GMU-700 |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.04~0.05(mm) |

| Performance Classification | High-End CNC Machine Tools |

| Certification | CE, ISO 9001 |

| Condition | New |

| Transport Package | Export Packing |

| Trademark | TOPSTAR |

| Origin | China |

| HS Code | 8456301090 |

| Production Capacity | 3000 Units Per Year |

Product Description

GMU-700 Five Axis Machining Center

Achieve efficient and accurate five-axis simultaneous machining.

Relying on the powerful rigidity presented by the fixed-beam gantry structure and the AFMING's unique mechanical transmission rotary table technology, the GMU630/700 Fearless series can achieve efficient and accurate combined turning and milling in combination with the gear anti-backlash patented technology and the torsion damping mechanism of the rotary table under the support of its powerful spindle research and development technology in the industry.

Fixed-beam gantry design to guarantee the high rigidity, high accuracy, and high efficiency and stability of the bed structure.The design method of finite element analysis in combination with dynamics optimization can greatly improve the static and dynamic characteristics of each component of the machine tool to ensure the overall rigidity, stability, and dynamic accuracy.

1. Moving parts optimized in terms of weight to achieve perfect dynamic performance.2. Z-axis optimized in terms of mechanics and dynamics to gain 30% more rigidity and dynamics than similar models.3. Extra-large area of vertical column base to provide stronger rigidity and stability.4. High-rigidity fixed-beam gantry structure is adopted to achieve excellent rigidity, thermal symmetric stability, and high-efficiency vibration suppression.5. An integral cross beam with a closed section to eliminate redundant mass and achieve high rigidity.6. Finite element analysis, calculation and optimization of whole-machine structure and moving parts.7. First-order natural frequency of the whole machine up to 67HZ, which can greatly improve the anti-seismic performance and the static and dynamic rigidity of the machine tools.8. Three-axis acceleration up to 0.8G.

Powerful high-rigidity and high-accuracy gear transmission rotary table technology.

The GMU-630/700 series has adopted the mechanical drive GTRT rotary table technology, which is uniquely developed by AFMING, for the first time in its class. With the double teeth stick anti-backlash drive for A axis and the dual worm + gear drive for C axis, the machine tools can present more powerful torque and higher rigidity, which, in combination with the original cradle torsion-damping technology, can ensure the excellent rotation accuracy of the rotary table and achieve more powerful output torque, higher rigidity, and permanent stability.

GTRT rotary tableA-axis: Servo motor + double teeth stick anti-backlash (lateral clearance anti-backlash patented technology)C-axis: Servo motor + Gear drive (gear anti-backlash technology + torsion damping technology) /DDRTravel (A/C): ±120°/360°Maximum speed (A/C): 20/30 rpmMaximum torque (A/C): 3625/1770 N.mRepeated positioning accuracy (A/C): 6/6Load bearing: 500 kgBrake torque (A/C): 5000/3500 N.mBrake oil pressure (A/C): 10/5 MPaC-axis torque motor (optional): Milling: 1 470 N.m / Turning: 1510 N.m

Easy operation

Based on ergonomic design, it has achieved extraordinary processing proximity and visibility as well as unrivalled ease of operation experience.

Detail Images

Application Fields

It is widely used in the processing of 3C products, aluminum alloy products, die-casting products, auto parts and so on.It's applicable for high-speed drilling and tapping processing.

| Name | Unit | GMU-630 | GMU-700D | GMU-700DT |

| System (Control unit) | SIEMENS-840D | HEIDENHAIN-iTNC640 | HEIDENHAIN-iTNC640 | |

| X/Y/Z axis travel | mm | 700/1180/550 (Y-axis travel includes too changing travel) | 700/1180/550 (Y-axis travel includes too changing travel) | 700/1180/550 (Y-axis travel includes too changing travel) ±120/360 |

| A/C axis travel | ° | ±120/360 | ±120/360 | ±120/360 |

| Spindle nose to table (when A axis is at 0 degree) | mm | 150-700 (this value is for mechanical spindles; for electric spindles, the value may be different ) | 150-700 (this value is for mechanical spindles; for electric spindles, the value may be different ) | 150-700 (this value is for mechanical spindles; for electric spindles, the value may be different ) |

| Table size | mm | φ630 | φ700 | φ700 |

| Maximum load bearing | kg | 500 | 400 | 300 |

| Spindle | ||||

| Spindle (standard) | ||||

| Maximum spindle speed/taper shank | rpm | 18000/HSK-A63 | 18000/HSK-A63 | 18000/HSK-A63 |

| Spindle power (S1/S6-40%) | KW | 20/28 | 20/28 | 20/28 |

| Torque (S1/S6-40%) | N.m | 58/81.2 | 58/81.2 | 58/81.2 |

| Feed system | ||||

| X/Y/Z axis rapid feed | m/min | 36/36/30 | 36/36/30 | 36/36/30 |

| Maximum cutting feed rate | m/min | 20 | 20 | 20 |

| Acceleration | m/s2 | 0.8 | m/s2 | 0.8 |

| A/C axis rapid feed rate | RPM/min | 20/30 | 20/80 (C-axis DDR) | 20/80 (C-axis DDR) |

| Rated torque A/C | N.m | 2080/1400 | 2080/860 | 2080/1080 |

| Static torque A/C | N.m | 3625/ 1770 | 3625/ 1470 | 3625/ 1510 |

| Brake torque A/C | N.m | 5000/ 3500 | 5000/ 3500 | 5000/ 3500 |

| Positioning accuracy (GB1 7421.22000) | ||||

| X/Y/ Z | mm | 0.008/ 0.008/ 0.008 | 0.008/ 0.008/ 0.008 | 0.008/ 0.008/ 0.008 |

| A/C | ARCSEC | 12/12 | 12/12 | 12/12 |

| Repeated positioning accuracy (GB1 7421.22000) | ||||

| X/Y/ Z | mm | 0.004/ 0.004/ 0.004 | 0.004/ 0.004/ 0.004 | 0.004/ 0.004/ 0.004 |

| A/C | ARCSEC | 6/6 | 6/6 | 6/6 |

| Automatic tool changing system | ||||

| Number of tool positions | PCS | 24T | 24T | 24T |

| Tool change time (tool-to-tool) | sec | 2.5s | 2.5s | 2.5s |

| Maximum tool length | mm | 300 | 300 | 300 |

| Maximum tool diameter /adjacent no tool | mm | φ 60/φ120 | φ 60/φ120 | φ 60/φ120 |

| Maximum tool weight | kg | 8 | 8 | 8 |

| Machine size | ||||

| Overall machine height | mm | 3900 | 3900 | 3900 |

| Floor area (Length × Width) | mm^2 | 4200*3200 | 4200*3200 | 4200*3200 |

| Net weight | kg | 16 | 16 | 16 |

| Power consumption | kw | 50 | 55 | 60 |

Company Profile