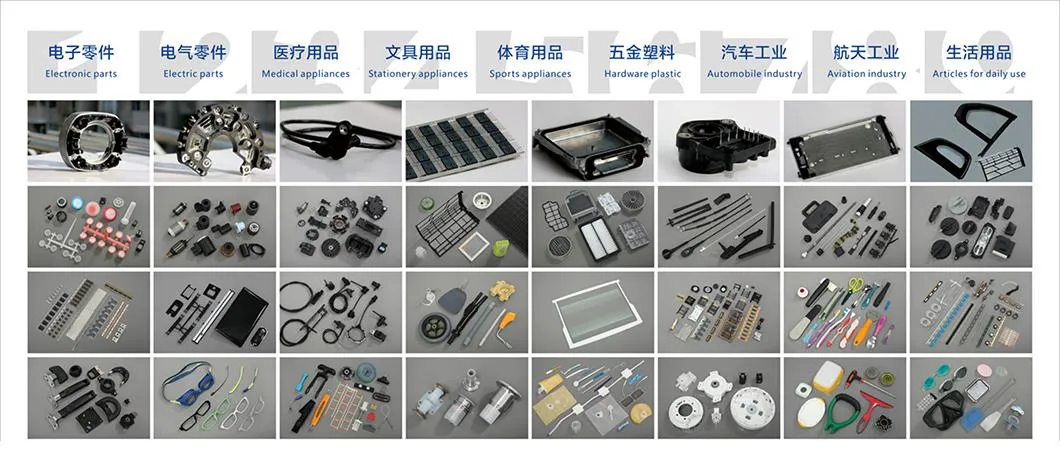

Category

High Speed Vertical Injection Molding Machine

Overview LIFENG specializes in manufacturina vertical iniection molding machines. The company vaccumulates exclusive tec

Overview

To satisfy various requirements of plastic products and consider global trends of safety and energy saving. LIFENG has created many exclusive machines. Maximizing consumers profit is always the first goal of the company.

Holding the principle of quality coming first, serving customer sinnovating technology, LIFENG constantly up grades service and provides entire technical support in pre-sale, sale and after-sale. The company keeps improvement. Provides win-win situations operates forever and has successful future together with costumers.

Today, by adopting technology from Europe and Japan, LIFENG has superior technology and most various machine types in domestic. Machines' quality is the internationally advanced level.

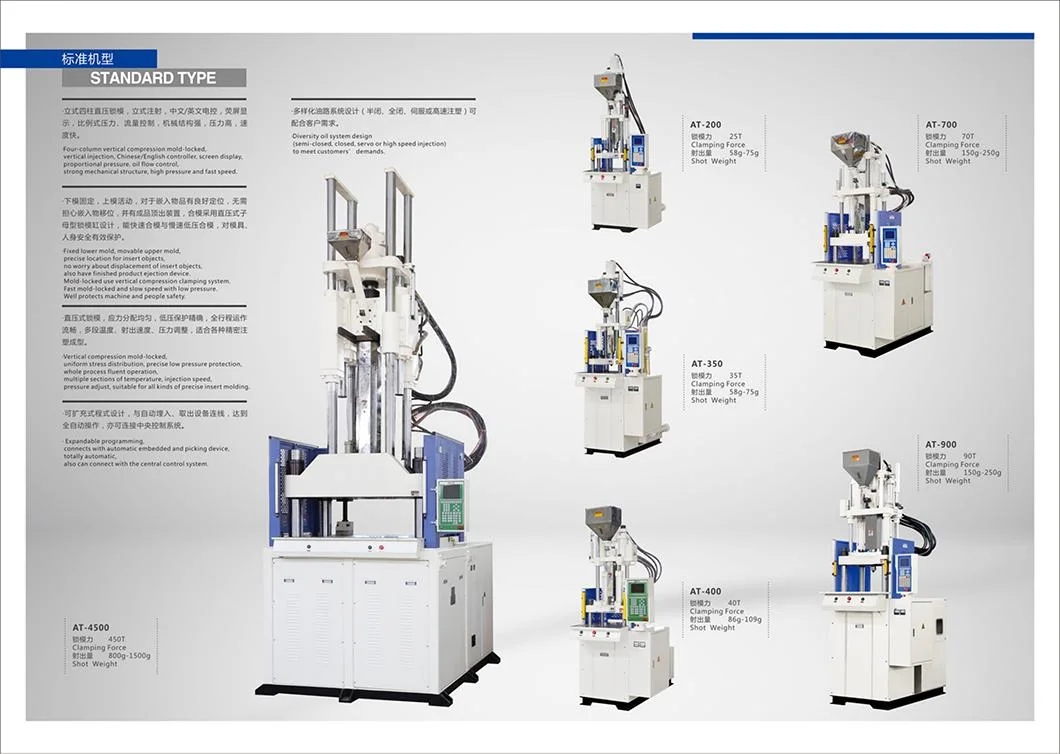

Machine Types:

AT: four-columns vertical locked mold vertical injection.

AC: vertical locked mold, horizontal injection (without vertical columns, three surfaces opened)

AK: four-columns vertical locked mold horizontal injection.

Clamping Force: 25T-650T Shot weight: 1g-6000g.

The three series can be divided into the following types:

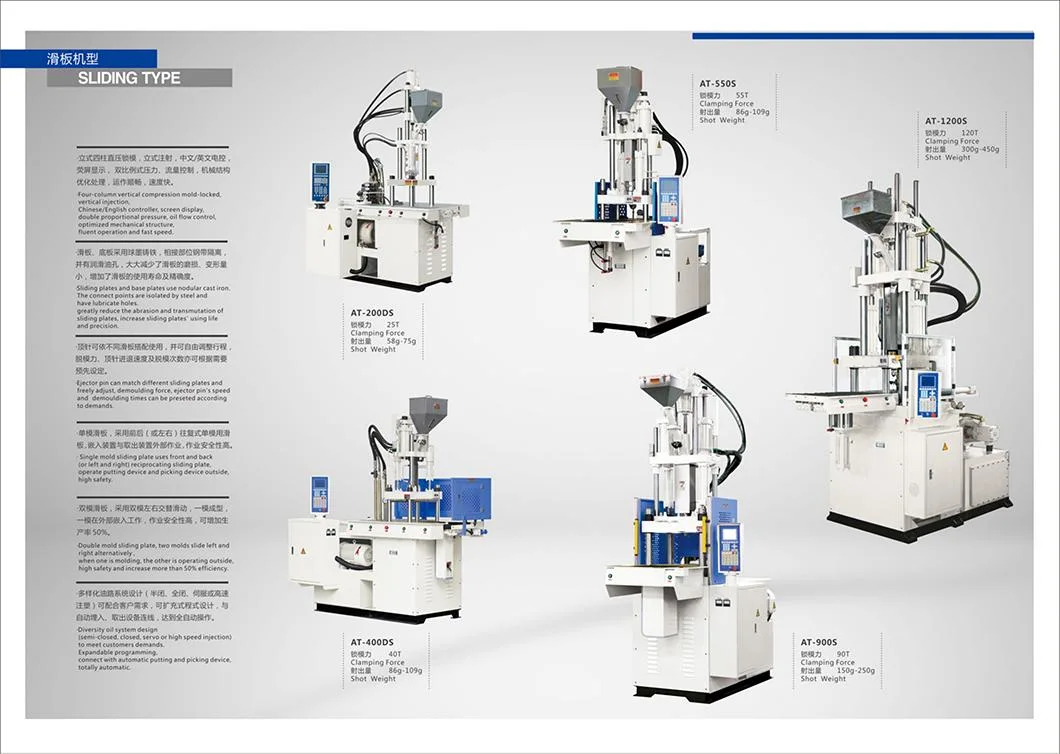

Standard Type: with one upper mold and one lower mold; it has rational structure and it is convenient to operate. Sliding Type(S):With one upper mold and one lower mold;Pick and place objects outside, operate conveniently and safely.

Double-sliding Type(DS): with one upper mold and two lower molds. the two lower molds work alternatively on the same horizontal plane. when one is molding, the other is at outside for picking objects. it can increase 50% efficiency and it is safe to operate.

Rotary Type(R): with one upper mold and two or more lower molds; the lower molds rotate 180°or 360°on the same horizontal plane. It also can highly increase etticiency and it is safe to operate.

We have independent technical team who focus on making machines, all the products

are made by our technical team.

Q2: What is the ability of your factory?

About injection molding machine, we could produce 50 sets machines per month.

about blow molding machine, we could produce 30sets machine per month

Q3: Do you have any technical supports about your products?

We have had long term collaboration with our partners worldwide, and we have a lot

of cooperation with a lot hef advanced manufacture company on the world.

Q4: Does the machine have an English manual and warranty card?

Each machine has a professional English operation manual and warranty card. In addition, we can provide electronic version of the English manual.

Q5: Do you have an aftermarket warranty for your products?

Warranty: General one year for whole injection molding machines.General one year for other types of whole machines.All customers that have bought LIFENG injection molding machines would be provided with a lifetime repair service of the machines.

Q6: Who is responsible for the installation and debugging of the machine I purchased?We the seller are fully responsible to send our engineers within two weeks from the date of the containers arrival to the buyers factory to commissioning the machine and training the staff of the buyer, the buyer should be responsible for a round trip economy ticket, a hotel and any other necessary accommodations for the seller's engineers, and engineer cost USD 80.00 per day.

Basic Info.

| Model NO. | AT-200 |

| Clamping Way | Hydraulic & Mechanical |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008, GMP |

| Transport Package | Standard Packaging |

| Trademark | LIFENG |

| Origin | Hangzhou, Zhejiang, China |

| HS Code | 8477101090 |

| Production Capacity | 50PCS One Week Can Supply |

Product Description

To satisfy various requirements of plastic products and consider global trends of safety and energy saving. LIFENG has created many exclusive machines. Maximizing consumers profit is always the first goal of the company.

Holding the principle of quality coming first, serving customer sinnovating technology, LIFENG constantly up grades service and provides entire technical support in pre-sale, sale and after-sale. The company keeps improvement. Provides win-win situations operates forever and has successful future together with costumers.

Today, by adopting technology from Europe and Japan, LIFENG has superior technology and most various machine types in domestic. Machines' quality is the internationally advanced level.

Machine Types:

AT: four-columns vertical locked mold vertical injection.

AC: vertical locked mold, horizontal injection (without vertical columns, three surfaces opened)

AK: four-columns vertical locked mold horizontal injection.

Clamping Force: 25T-650T Shot weight: 1g-6000g.

The three series can be divided into the following types:

Standard Type: with one upper mold and one lower mold; it has rational structure and it is convenient to operate. Sliding Type(S):With one upper mold and one lower mold;Pick and place objects outside, operate conveniently and safely.

Double-sliding Type(DS): with one upper mold and two lower molds. the two lower molds work alternatively on the same horizontal plane. when one is molding, the other is at outside for picking objects. it can increase 50% efficiency and it is safe to operate.

Rotary Type(R): with one upper mold and two or more lower molds; the lower molds rotate 180°or 360°on the same horizontal plane. It also can highly increase etticiency and it is safe to operate.

We have independent technical team who focus on making machines, all the products

are made by our technical team.

Q2: What is the ability of your factory?

About injection molding machine, we could produce 50 sets machines per month.

about blow molding machine, we could produce 30sets machine per month

Q3: Do you have any technical supports about your products?

We have had long term collaboration with our partners worldwide, and we have a lot

of cooperation with a lot hef advanced manufacture company on the world.

Q4: Does the machine have an English manual and warranty card?

Each machine has a professional English operation manual and warranty card. In addition, we can provide electronic version of the English manual.

Q5: Do you have an aftermarket warranty for your products?

Warranty: General one year for whole injection molding machines.General one year for other types of whole machines.All customers that have bought LIFENG injection molding machines would be provided with a lifetime repair service of the machines.

Q6: Who is responsible for the installation and debugging of the machine I purchased?We the seller are fully responsible to send our engineers within two weeks from the date of the containers arrival to the buyers factory to commissioning the machine and training the staff of the buyer, the buyer should be responsible for a round trip economy ticket, a hotel and any other necessary accommodations for the seller's engineers, and engineer cost USD 80.00 per day.