Category

Special Mould for Heat Insulation Strip PA66/Nylon and Plastic Thermal Barrel Strip Production Plant

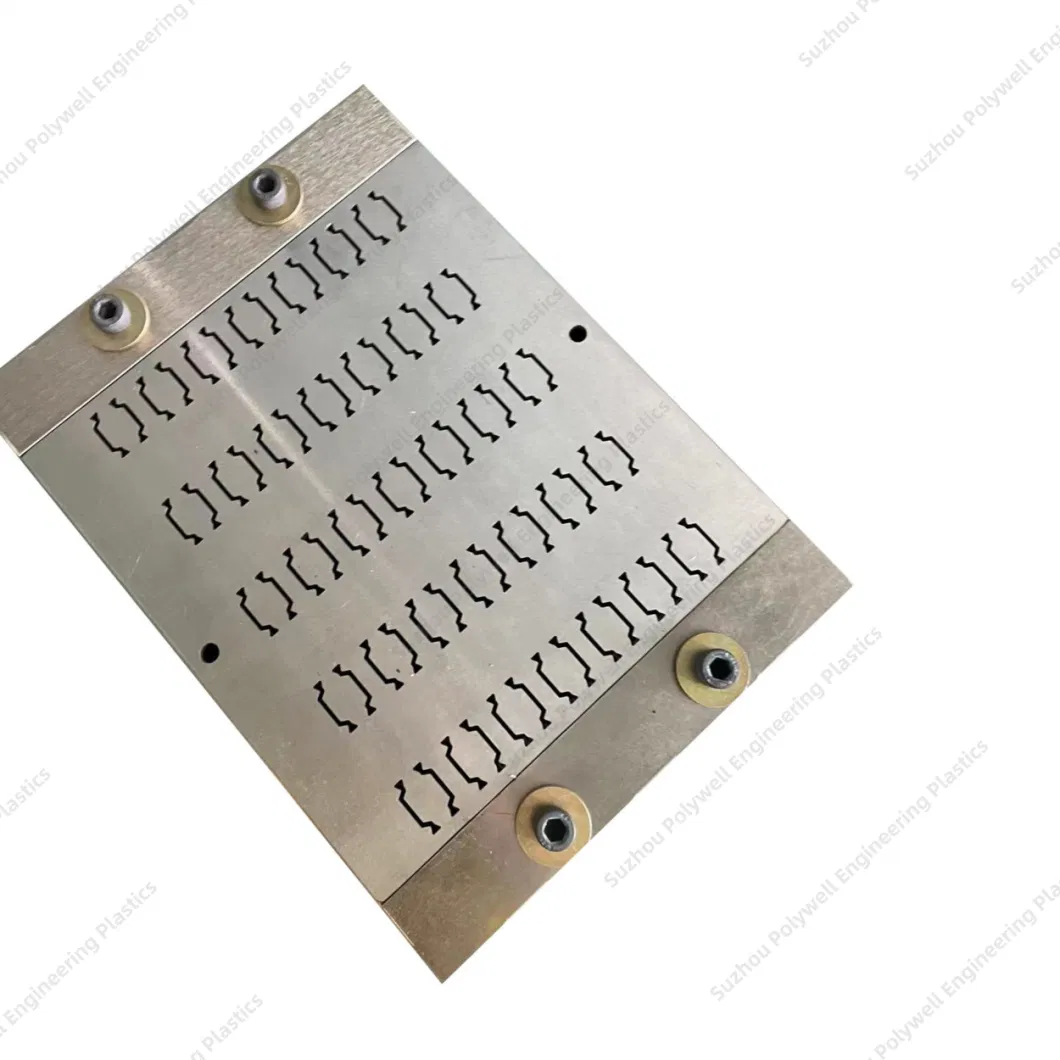

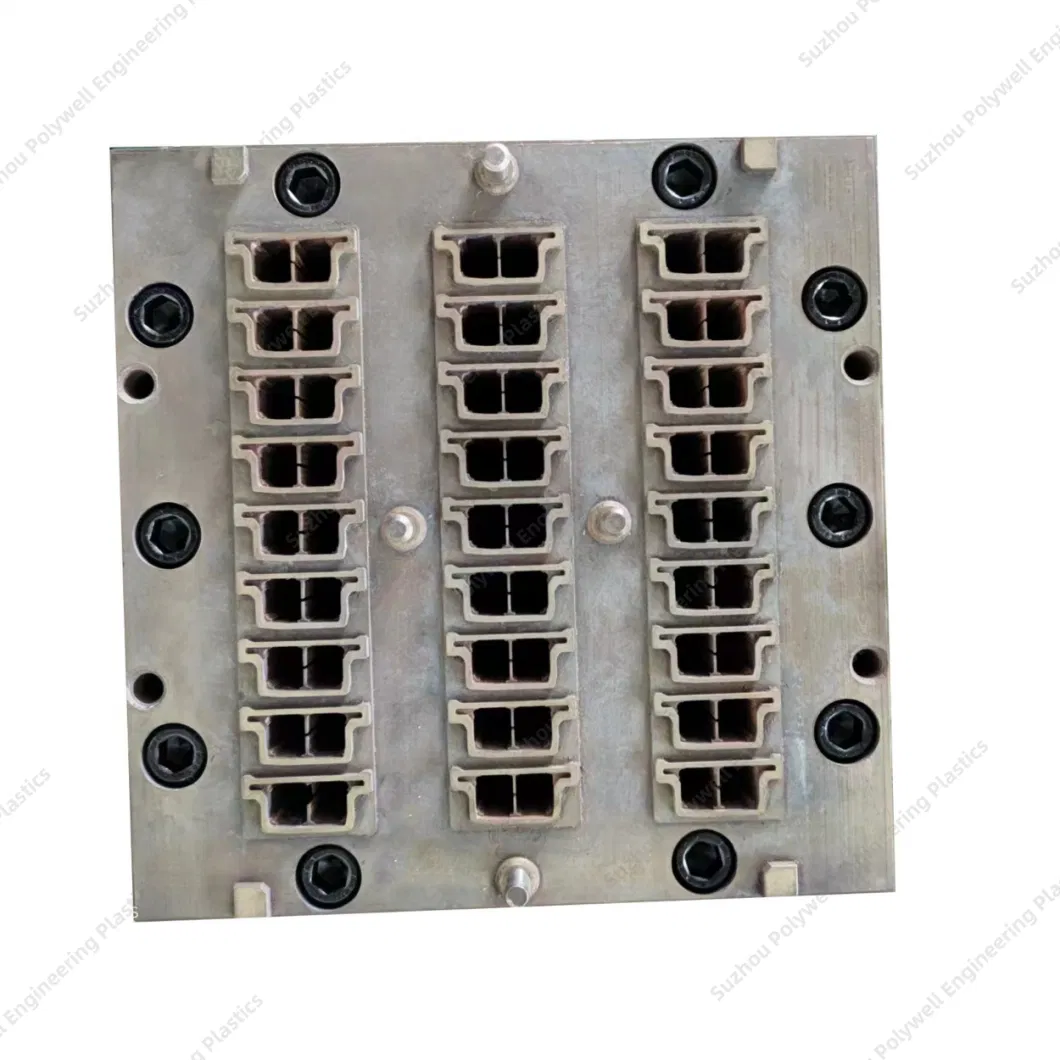

Special Mould for Heat Insulation Strip PA66/Nylon and Plastic Thermal Barrel Strip Production Plant Polywell mould can

Basic Info.

| Model NO. | PW-M10 |

| Nose Application | Profile Molding |

| Outlet | Direct Feeding |

| Pressure of Nose | High Pressure |

| Non Metal Mould | Plastic Mould |

| Metal Mould | Die Casting |

| After-sales Service | Engineers Available to Service Overseas |

| Standard | Hasco |

| Condition | New |

| Design Software | Autocad |

| Cooling System | Water Cooling |

| Process Combination Type | Compound Die |

| Weight | 60-200kg |

| Transport Package | Plywood Case |

| Specification | Hot Plate and Cold Plate |

| Trademark | Polywell |

| Origin | Zhangjiagang, China |

| HS Code | 8477900000 |

| Production Capacity | 80sets/Month |

Product Description

Special Mould for Heat Insulation Strip PA66/Nylon and Plastic Thermal Barrel Strip Production PlantPolywell mould can meet the needs of the market and customer.Polywell has its own design and development of nylon insulation strip automatic extrusion production line with high stability, high yield, high adaptability.

The utility model mainly uses the special screw to make the polyamide and the glass fiber mixed good. Heat insulating rubber strips are widely applied to the doors, windows and curtain wall aluminum sheets through the different sections of the die.

Product Specifications:

| Product Name | Mould for thermal barrier strips extrusion machine |

| Brand | Polywell |

| Size | Various types |

| Mold material | Mold steel |

| Product | PA66 thermal barrier strips |

| Runner | Cold/Hot runner |

| Mould cavity | Multi-cavity |

| Mould weight | 60kg-200kg |

| Service | Provide complete set of production press and technology and best after sale service. |

| Lead time | 25-35 working days |

| Package | Plywood case |

Detail introduction:

PA66 granules and fiber glass are dired and get into the barrel through the hopper. Screw and pellets contact with the rotation of the screw is forced to promote the spiral groove die direction.Because the screw barrel gap is small, the granule material is hot body under great pressure in the forward process, it is plasticizied to nylon thermosol through the high temperature of the electric heating ring body. Nylon plastic and plastic compression heating hot melt by extrusion molding, after traction, cutting or rolling become adiabatic adhesive tape products.The host adopts imported inverter and traction, speed stability, ensure the main, auxiliary synchronous speed.We use German technology to make the mould, so the surface of thermal insulation strips are beautiful, accurate shape and with high strength.We use imported Japanese RKC temperature control table, so that the accuracy of the temperature can be controled in ±2 degrees.

Our Advantages:

1. Our engineers follow the molds' production every week to make sure all of them are in schedule 2. After trial production, we will check the samples to make sure everything are right 3. We will send the sample and dimension report to our clients for approval4. After everything is ok, we will do final inspection on the molds and products before shipment.

Shape: We can make the shape according to customers' requirements.Package: Plywood case package

Please feel free to contact us if you have any questions.

Name:Camille CaiAddress:Jinfeng Town, Zhangjiagang City, Jiangsu Province, China